NWT Cylinders

Accessories

NWT is a new

range of ISO 15552 cylinders with new design and new technology in

production process, to satisfy needs

of high quality performances and more competitiveness. NWT was

developed by using new materials for parts

and new ways of producing those parts as well as new assembling and

testing methods. As results, NWT cylinders are solid,

high performing, very reliable and much competitive.

|

|

|

Quality

International 2008 Winner

|

Heads - Die-cast

aluminium alloy.

Piston

rod - Rolled burnished stainless steel X20 Cr13.

Barrel

- Anodized profiled aluminium

tube.

Seals

- Poliurethan.

Cushioning

- Pneumatic adjusting cushions.

Buffers

- Mechanical.

Environment

temperature range - -10 °C ÷

+80 °C.

Temperature

range of medium - 0 °C ÷ +40

°C.

Lubrication

- Not required.

Medium

- Filtered air.

Max

operating pressure - 10 bar.

|

Standard stroke

|

|

Bore

|

25

|

50

|

80

|

100

|

125

|

160

|

200

|

250

|

300

|

350

|

400

|

450

|

500

|

600

|

700

|

800

|

900

|

1000

|

|

32

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

|

|

|

|

|

|

40

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

|

|

|

|

|

|

50

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

|

|

|

|

|

|

63

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

|

|

|

|

|

|

80

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

|

100

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

125 |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

|

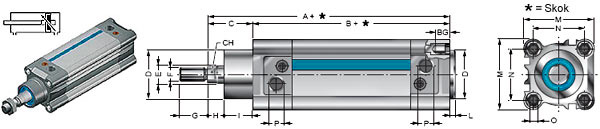

Bore

|

A

|

B

|

C

|

ØD

|

ØE

|

ØF

|

G

|

H

|

I

|

L

|

M

|

N

|

ØO

|

ØP

|

BG

|

CH

|

|

32

|

120

|

94

|

26

|

30

|

12

|

M10x1,25

|

20

|

8

|

18

|

4

|

45

|

32,5

|

M6

|

G1/8

|

16

|

10

|

|

40

|

135

|

105

|

30

|

35

|

16

|

M12x1,25

|

24

|

8,5

|

21,5

|

4

|

54

|

38

|

M6

|

G1/4

|

16

|

3

|

|

50

|

143

|

106

|

37

|

40

|

20

|

M16x1,5

|

32

|

9

|

28

|

4

|

64

|

46,5

|

M8

|

G1/4

|

16

|

17

|

|

63

|

158

|

121

|

37

|

45

|

20

|

M16x1,5

|

32

|

8,5

|

28,5

|

4

|

75

|

56,5

|

M8

|

G3/8

|

16

|

17

|

|

80

|

174

|

128

|

46

|

45

|

25

|

M20x1,5

|

40

|

11,5

|

34,5

|

4

|

93

|

72

|

M10

|

G3/8

|

18

|

21

|

|

100

|

189

|

138

|

51

|

55

|

25

|

M20x1,5

|

40

|

13

|

38

|

4

|

110

|

89

|

M10

|

G1/2

|

18

|

21

|

| 125 |

225 |

160 |

65 |

60 |

30 |

M27x2 |

54 |

30 |

35 |

5 |

142 |

110 |

M12 |

G1/2 |

22 |

27 |

| Newton

VS/VV/SEA/SEP |

| |

|

Bore

|

A

|

B

|

C

|

ØD

|

ØE

|

ØF

|

G

|

H

|

H1

|

I

|

M

|

N

|

ØO

|

ØP

|

BG

|

CH

|

|

32

|

120

|

94

|

26

|

30

|

12

|

M10x1,25

|

20

|

8

|

26

|

18

|

45

|

32,5

|

M6

|

G1/8

|

16

|

10

|

|

40

|

135

|

105

|

30

|

35

|

16

|

M12x1,25

|

24

|

8,5

|

30

|

21,5

|

54

|

38

|

M6

|

G1/4

|

16

|

3

|

|

50

|

143

|

106

|

37

|

40

|

20

|

M16x1,5

|

32

|

9

|

37

|

28

|

64

|

46,5

|

M8

|

G1/4

|

16

|

17

|

|

63

|

158

|

121

|

37

|

45

|

20

|

M16x1,5

|

32

|

8,5

|

37

|

28,5

|

75

|

56,5

|

M8

|

G3/8

|

16

|

17

|

|

80

|

174

|

128

|

46

|

45

|

25

|

M20x1,5

|

40

|

11,5

|

46

|

34,5

|

93

|

72

|

M10

|

G3/8

|

18

|

21

|

|

100

|

189

|

138

|

51

|

55

|

25

|

M20x1,5

|

40

|

13

|

51

|

38

|

110

|

89

|

M10

|

G1/2

|

18

|

21

|

| 125 |

225 |

160 |

65 |

60 |

30 |

M27x2 |

54 |

30 |

65 |

35 |

142 |

110 |

M12 |

G1/2 |

22 |

27 |

____________________________________________________________________________________________________________________

|