NSK Compact Cylinders

Accessories

|

|

|

NSK series

is a completely new range of compact cylinders. It has been worked out

in one set of common basic

components for a final assembly to ISO 21287 standard as well as UNITOP

standard, which is covered by patent.

An extremely construction simplicity, new design and advanced

technology make the compact series NSK highly competitive, able to meet

even the hardest request of performance and reliability and give it a

wide duty flexibility.

What also greatly significant is the advantage of a drastic reduction

in construction elements, though saving the need of offering 2 standard

version of product.

|

|

|

|

Technical features

|

Head:

Die-cast aluminium alloy.

Piston rod: Ø16 ÷ 25

stainless steel X5CrNi1810,

Ø32 ÷ 100 stainless steel X20Cr13.

Barrel: Anodized profiled aluminium tube.

Seals: Polyurethan.

Cushioning: Mechanical buffers.

Ambient temperature range: -20 °C

÷ +80 °C.

Temperature range of medium: 0 °C

÷ +40 °C.

Lubrication: Not required.

Medium: Filtered air.

Max operating pressure: 10 bar.

|

|

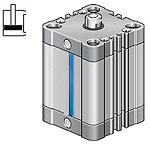

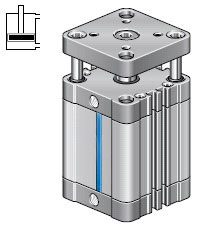

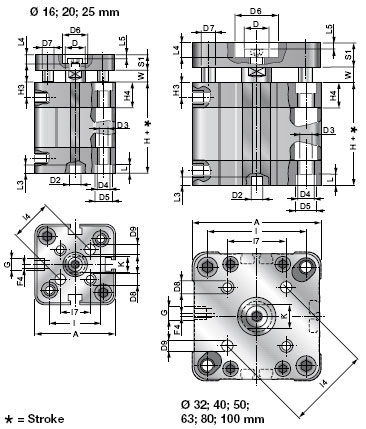

NSK - Double acting magnetic cylinder

|

|

| Standard ISO 21287 |

|

|

|

|

|

|

|

|

|

|

|

|

| Ø |

A |

ØD |

ØD2 |

ØD3 |

ØD4 |

ØD5 |

G |

H3 |

H4 |

I |

K |

L |

L3 |

W |

F4 |

H |

| 16 |

29,2 |

8 |

6 |

3,3 |

M4 |

6 |

M5 |

7 |

12,8 |

18 |

6 |

3,5 |

2,2 |

4,5 |

0 |

37

(±0,5) |

| 20 |

37 |

10 |

6 |

4,2 |

M5 |

7,5 |

M5 |

7 |

12,3 |

22 |

8 |

2,5 |

2,5 |

6 |

4 |

37

(±0,5) |

| 25 |

41 |

10 |

6 |

4,2 |

M5 |

7,5 |

M5 |

7,5 |

13,5 |

26 |

8 |

2,5 |

2,5 |

6 |

3 |

39

(±0,5) |

| 32 |

49,2 |

12 |

6 |

5,2 |

M6 |

9 |

G1/8 |

7,5 |

15 |

32,5 |

10 |

2 |

2 |

7 |

0 |

44

(±0,5) |

| 40 |

57,2 |

12 |

6 |

5,2 |

M6 |

9 |

G1/8 |

7,5 |

15 |

38 |

10 |

2 |

2 |

7 |

0 |

45

(±0,7) |

| 50 |

67 |

16 |

8 |

6,7 |

M8 |

10,5 |

G1/8 |

7,5 |

14,6 |

46,5 |

13 |

2,5 |

2,5 |

8 |

0 |

45

(±0,7) |

| 63 |

80 |

16 |

8 |

6,7 |

M8 |

10,5 |

G1/8 |

8 |

15,5 |

56,5 |

13 |

2,5 |

2,5 |

8 |

0 |

49

(±0,8) |

| 80 |

102,6* |

20 |

8 |

8,5 |

M10 |

10,5 |

G1/8 |

9 |

17 |

72 |

17 |

2,5 |

2,5 |

10 |

0 |

54

(±0,8) |

| 100 |

124* |

25 |

8 |

8,5 |

M10 |

10,5 |

G1/4" |

10 |

20 |

89 |

22 |

3 |

3 |

10 |

0 |

67

(±1,0) |

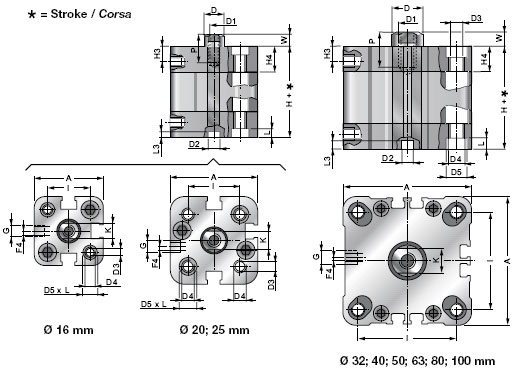

| Standard UNITOP |

|

|

|

|

|

|

|

|

|

|

|

|

| Ø |

A |

ØD |

ØD2 |

ØD3 |

ØD4 |

ØD5 |

G |

H3 |

H4 |

I |

K |

L |

L3 |

W |

F4 |

H |

| 16 |

29,2 |

8 |

6 |

3,3 |

M4 |

6 |

M5 |

7 |

12,8 |

18 |

6 |

3,5 |

2,2 |

4,5 |

0 |

38

(±0,5) |

| 20 |

37 |

10 |

6 |

4,2 |

M5 |

7,5 |

M5 |

7 |

12,3 |

22 |

8 |

2,5 |

2,5 |

4,5 |

4 |

38

(±0,5) |

| 25 |

41 |

10 |

6 |

4,2 |

M5 |

7,5 |

M5 |

7,5 |

13,5 |

26 |

8 |

2,5 |

2,5 |

5,5 |

3 |

39,5

(±0,5) |

| 32 |

49,2 |

12 |

6 |

5,2 |

M6 |

9 |

G1/8 |

7,5 |

15 |

32 |

10 |

2 |

2 |

6 |

0 |

44,5

(±0,5) |

| 40 |

57,2 |

12 |

6 |

5,2 |

M6 |

9 |

G1/8 |

7,5 |

15 |

42 |

10 |

2 |

2 |

6,5 |

0 |

45,5

(±0,7) |

| 50 |

67 |

16 |

8 |

6,7 |

M8 |

10,5 |

G1/8 |

7,5 |

14,6 |

50 |

13 |

2,5 |

2,5 |

7,5 |

0 |

45,5

(±0,7) |

| 63 |

80 |

16 |

8 |

6,7 |

M8 |

10,5 |

G1/8 |

8 |

15,5 |

62 |

13 |

2,5 |

2,5 |

7,5 |

0 |

50

(±0,8) |

| 80 |

102,6* |

20 |

8 |

8,5 |

M10 |

10,5 |

G1/8 |

9 |

17 |

82 |

17 |

2,5 |

2,5 |

8 |

0 |

56

(±0,8) |

| 100 |

124* |

25 |

8 |

8,5 |

M10 |

10,5 |

G1/4" |

10 |

20 |

103 |

22 |

3 |

3 |

10 |

0 |

66,5

(±1,0) |

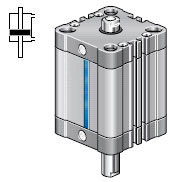

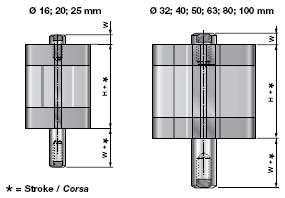

NSK .. P - Double acting magnetic trough

rod cylinder

|

|

| Standard ISO 21287 |

|

Standard UNITOP |

| Ø |

W |

H |

|

Ø |

W |

H |

| 16 |

4,5 |

37

(±0,5) |

|

16 |

4,5 |

38

(±0,5) |

| 20 |

6 |

37

(±0,5) |

|

20 |

4,5 |

38

(±0,5) |

| 25 |

6 |

39

(±0,5) |

|

25 |

5,5 |

39,5

(±0,5) |

| 32 |

7 |

44

(±0,5) |

|

32 |

6 |

44,5

(±0,5) |

| 40 |

7 |

45

(±0,7) |

|

40 |

6,5 |

45,5

(±0,7) |

| 50 |

8 |

45

(±0,8) |

|

50 |

7,5 |

45,5

(±0,7) |

| 63 |

8 |

49

(±0,8) |

|

63 |

7.5 |

50

(±0,8) |

| 80 |

10 |

54

(±0,8) |

|

80 |

8 |

56

(±0,8) |

| 100 |

10 |

67

(±1,0) |

|

100 |

10 |

66,5

(±1,0) |

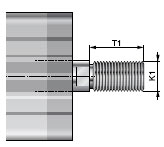

NSK .. M - Threaded male piston rod

version

|

|

| Standard ISO 21287 |

|

Standard UNITOP |

| Ø |

K1 |

T1 |

|

Ø |

K1 |

T1 |

| 16 |

M8x1,25 |

20 |

|

16 |

M8x1,25 |

20 |

| 20 |

M8x1,25 |

16 |

|

20 |

M8x1,25 |

22 |

| 25 |

M8x1,25 |

16 |

|

25 |

M8x1,25 |

22 |

| 32 |

M10x1,25 |

19 |

|

32 |

M10x1,25 |

22 |

| 40 |

M10x1,25 |

19 |

|

40 |

M10x1,25 |

22 |

| 50 |

M12x1,25 |

22 |

|

50 |

M12x1,25 |

24 |

| 63 |

M12x1,25 |

22 |

|

63 |

M12x1,25 |

24 |

| 80 |

M16x1,5 |

28 |

|

80 |

M16x1,5 |

32 |

| 100 |

M16x1,5 |

28 |

|

100 |

M16x1,5 |

40 |

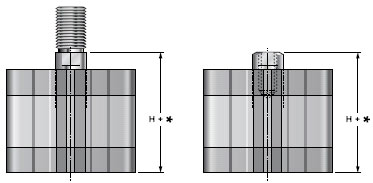

NSK .. F - Threaded Female piston rod

version

|

|

| Standard ISO 21287 |

|

Standard UNITOP |

| Ø |

ØD1 |

P |

|

Ø |

K1 |

T1 |

| 16 |

M4 |

8 |

|

16 |

M4 |

8 |

| 20 |

M6 |

10 |

|

20 |

M6 |

10 |

| 25 |

M6 |

10 |

|

25 |

M6 |

10 |

| 32 |

M8 |

12 |

|

32 |

M8 |

12 |

| 40 |

M8 |

12 |

|

40 |

M8 |

12 |

| 50 |

M10 |

16 |

|

50 |

M8 |

16 |

| 63 |

M10 |

16 |

|

63 |

M8 |

16 |

| 80 |

M12 |

20 |

|

80 |

M10 |

20 |

| 100 |

M12 |

20 |

|

100 |

M12 |

20 |

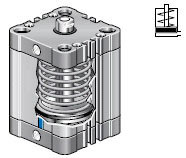

NSK .. SEA - Simple acting front spring

|

|

| Standard ISO 21287 |

|

|

|

|

|

|

| Ø |

F

spring max

(stroke 0 mm) |

F

spring min

(stroke 25 mm) |

H ISO 21287 |

H UNITOP |

|

Ø |

F spring max

(stroke 0 mm) |

F spring min

(stroke 25 mm) |

H ISO 21287 |

H UNITOP |

| 16 |

21 |

12 |

37

(±0,5) |

38

(±0,5) |

|

16 |

21 |

12 |

47 (±0,5) |

48

(±0,5) |

| 20 |

39 |

22 |

37

(±0,5) |

38

(±0,5) |

|

20 |

39 |

22 |

47

(±0,5) |

48

(±0,5) |

| 25 |

45 |

28 |

39

(±0,5) |

39,5

(±0,5) |

|

25 |

45 |

28 |

59

(±0,5) |

59,5

(±0,5) |

| 32 |

45 |

28 |

44

(±0,5) |

44,5

(±0,5) |

|

32 |

45 |

28 |

64

(±0,5) |

64,5

(±0,5) |

| 40 |

61 |

39 |

45

(±0,7) |

45,5

(±0,7) |

|

40 |

61 |

39 |

65

(±0,7) |

66,5

(±0,7) |

| 50 |

90 |

58 |

45

(±0,7) |

45,7

(±0,7) |

|

50 |

90 |

58 |

65

(±0,7) |

65,5

(±0,7) |

| 63 |

95 |

62 |

49

(±0,8) |

50

(±0,8) |

|

63 |

95 |

62 |

69

(±0,8) |

70

(±0,8) |

| 80 |

115 |

150 |

54

(±0,8) |

56

(±0,8) |

|

80 |

115 |

150 |

84

(±0,8) |

86

(±0,8) |

| 100 |

125 |

160 |

67

(±1,0) |

66,5

(±1,0) |

|

100 |

125 |

160 |

97

(±1,0) |

96,5

(±1,0) |

NSK .. SEP - Simple acting rear spring

NSK .. AR - Simple acting rear spring

|

| Standard ISO 21287 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Ø |

A |

ØD |

ØD2 |

ØD3 |

ØD4 |

ØD5 |

G |

H3 |

H4 |

I |

K |

L |

L3 |

W |

F4 |

S1 |

W |

H |

| 16 |

29,2 |

8 |

6 |

3,3 |

M4 |

6 |

M5 |

7 |

12,8 |

18 |

6 |

3,5 |

2,2 |

4,5 |

0 |

6 |

4,5 |

37

(±0,5) |

| 20 |

37 |

10 |

6 |

4,2 |

M5 |

7,5 |

M5 |

7 |

12,3 |

22 |

8 |

4,2 |

2,5 |

6 |

4 |

8 |

4,5 |

37

(±0,5) |

| 25 |

41 |

10 |

6 |

4,2 |

M5 |

7,5 |

M5 |

7,5 |

13,5 |

26 |

8 |

4,2 |

2,5 |

6 |

3 |

8 |

5,5 |

39

(±0,5) |

| 32 |

49,2 |

12 |

6 |

5,2 |

M6 |

9 |

G1/8 |

7,5 |

15 |

32,5 |

10 |

4,5 |

2 |

7 |

0 |

10 |

6 |

44

(±0,5) |

| 40 |

57,2 |

12 |

6 |

5,2 |

M6 |

9 |

G1/8 |

7,5 |

15 |

38 |

10 |

4,2 |

2 |

7 |

0 |

10 |

6,5 |

45

(±0,7) |

| 50 |

67 |

1616 |

8 |

6,7 |

M8 |

10,5 |

G1/8 |

7,5 |

14,6 |

46,5 |

13 |

4,7 |

2,5 |

8 |

0 |

12 |

7,5 |

45

(±0,7) |

| 63 |

80 |

16 |

8 |

6,7 |

M8 |

10,5 |

G1/8 |

8 |

15,5 |

56,5 |

13 |

5,2 |

2,5 |

8 |

0 |

12 |

7,5 |

49

(±0,8) |

| 80 |

102,6* |

20 |

8 |

8,5 |

M10 |

13,5 |

G1/8 |

9 |

17 |

72 |

17 |

5,2 |

2,5 |

10 |

0 |

14 |

8 |

54

(±0,8) |

| 100 |

124* |

25 |

8 |

8,5 |

M10 |

13,5 |

G1/4* |

10 |

20 |

89 |

22 |

5,2 |

3 |

10 |

0 |

14 |

10 |

67

(±1,0) |

| Standard UNITOP |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Ø |

A |

ØD |

ØD2 |

ØD3 |

ØD4 |

ØD5 |

G |

H3 |

H4 |

I |

K |

L |

L3 |

W |

F4 |

S1 |

W |

H |

| 16 |

29,2 |

8 |

6 |

3,3 |

M4 |

6 |

M5 |

7 |

12,8 |

18 |

6 |

3,5 |

2,2 |

4,5 |

0 |

6 |

4,5 |

38

(±0,5) |

| 20 |

37 |

10 |

6 |

4,2 |

M5 |

7,5 |

M5 |

7 |

12,3 |

22 |

8 |

4,2 |

2,5 |

6 |

4 |

8 |

4,5 |

38

(±0,5) |

| 25 |

41 |

10 |

6 |

4,2 |

M5 |

7,5 |

M5 |

7,5 |

13,5 |

26 |

8 |

4,2 |

2,5 |

6 |

3 |

8 |

5,5 |

39,5

(±0,5) |

| 32 |

49,2 |

12 |

6 |

5,2 |

M6 |

9 |

G1/8 |

7,5 |

15 |

32 |

10 |

4,5 |

2 |

7 |

0 |

10 |

6 |

44,5

(±0,5) |

| 40 |

57,2 |

12 |

6 |

5,2 |

M6 |

9 |

G1/8 |

7,5 |

15 |

42 |

10 |

4,2 |

2 |

7 |

0 |

10 |

6,5 |

45,5

(±0,7) |

| 50 |

67 |

1616 |

8 |

6,7 |

M8 |

10,5 |

G1/8 |

7,5 |

14,6 |

50 |

13 |

4,7 |

2,5 |

8 |

0 |

12 |

7,5 |

45,5

(±0,7) |

| 63 |

80 |

16 |

8 |

6,7 |

M8 |

10,5 |

G1/8 |

8 |

15,5 |

62 |

13 |

5,2 |

2,5 |

8 |

0 |

12 |

7,5 |

50

(±0,8) |

| 80 |

102,6* |

20 |

8 |

8,5 |

M10 |

13,5 |

G1/8 |

9 |

17 |

82 |

17 |

5,2 |

2,5 |

10 |

0 |

14 |

8 |

56

(±0,8) |

| 100 |

124* |

25 |

8 |

8,5 |

M10 |

13,5 |

G1/4* |

10 |

20 |

103 |

22 |

5,2 |

3 |

10 |

0 |

14 |

10 |

66,5

(±1,0) |

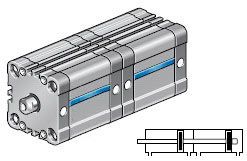

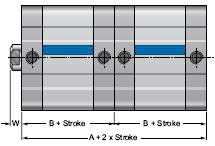

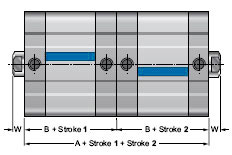

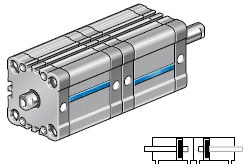

NSK .. TN2 - Multi-thrust tandem (Standard ISO 21287, Standard

UNITOP)

|

| Ø |

A |

B |

|

|

|

|

| 32 |

88,4 |

44,2 |

|

|

|

|

| 40 |

90,4 |

44,2 |

|

|

|

|

| 50 |

90,4 |

44,2 |

|

|

|

|

| 63 |

9 |

49,5 |

|

|

|

|

| 80 |

110 |

55 |

|

|

|

|

| 100 |

133,4 |

66,7 |

|

|

|

|

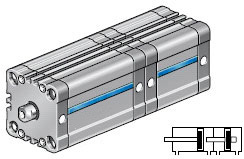

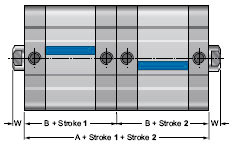

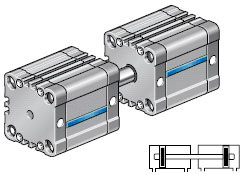

NSK .. BS - Multi-Position (Standard ISO 21287, Standard

UNITOP)

|

| Ø |

A |

B |

|

|

|

|

| 32 |

88,4 |

44,2 |

|

|

|

|

| 40 |

90,4 |

44,2 |

|

|

|

|

| 50 |

90,4 |

44,2 |

|

|

|

|

| 63 |

9 |

49,5 |

|

|

|

|

| 80 |

110 |

55 |

|

|

|

|

| 100 |

133,4 |

66,7 |

|

|

|

|

NSK .. CNP - Rear opposed (Standard ISO 21287, Standard

UNITOP)

|

| Ø |

A |

B |

|

|

|

|

| 16 |

76 |

38 |

|

|

|

|

| 20 |

76 |

38 |

|

|

|

|

| 25 |

79 |

39,5 |

|

|

|

|

| 32 |

88,4 |

44,2 |

|

|

|

|

| 40 |

90,4 |

44,2 |

|

|

|

|

| 50 |

90,4 |

44,2 |

|

|

|

|

| 63 |

9 |

49,5 |

|

|

|

|

| 80 |

110 |

55 |

|

|

|

|

| 100 |

133,4 |

66,7 |

|

|

|

|

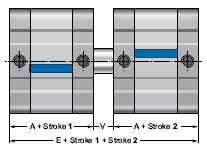

NSK .. CNF - Front opposed (Standard ISO 21287, Standard

UNITOP)

|

| Ø |

A |

B |

V |

|

|

|

| 16 |

85 |

38,8 |

9 |

|

|

|

| 20 |

85 |

38 |

9 |

|

|

|

| 25 |

90 |

39,5 |

11 |

|

|

|

| 32 |

100,4 |

44,2 |

12 |

|

|

|

| 40 |

103,4 |

45,2 |

13 |

|

|

|

| 50 |

104,4 |

45,2 |

15 |

|

|

|

| 63 |

114 |

49,5 |

15 |

|

|

|

| 80 |

126 |

55 |

16 |

|

|

|

| 100 |

153,4 |

66,7 |

20 |

|

|

|

|