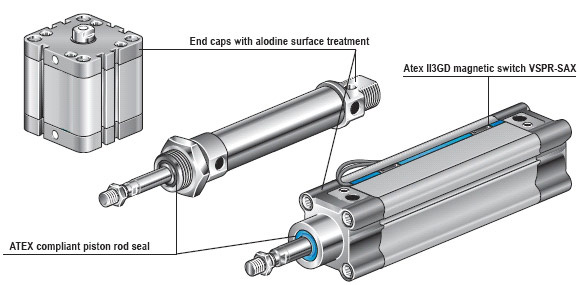

ATEX

cylinders satisfy all directives94/9/EC to avoid mechanical risks of

ignition in explosive atmosphere (category II3GD). Design, materials

and technical solutions are made to prevent mechanical sparks,

electrostatic charges, heating of surfaces due to friction, etc.

All these solutions make ATEX cylinders in “constructional

safety”.

They grant the earthing of all their parts, due to alodine surface

treatment of end caps. This treatment grants protection to products,

while allows electrical conduction. All the parts are Atex compliant

and cylinders have overcome Atex impact tests and protection degree

IP65 tests.

|

|

ATEX Cylinders

|

|

Technical features

|

Atex category II3GD

IP65 protection degree

Polyuretan seals (XNWT, XSK, XXJSS), polyuretan and NBR (XDVM; XACM;

XDSM).

End caps with alodine surface treatment

Stainless steel piston rod

Medium T: 0°<Tfluido<25°C

Enviroment T: -5°<Tamb<50°C

Medium: filtered air (quality 5 ISO 8573-1)

Lubrication: not required

|