Accesories

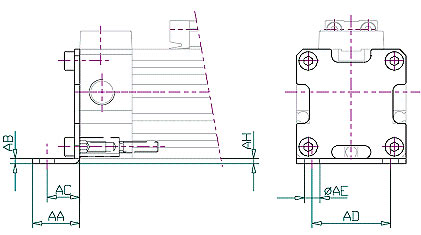

SLXP Mounting brackets

|

|

|

|

|

|

AA

|

AB

|

AC

|

AD

|

AE

|

AH

|

|

|

|

|

|

|

|

|

|

|

SLXP/018

|

Ø 18

|

15

|

2

|

10

|

20

|

Ø 6

|

2

|

|

SLXP/025

|

Ø 25

|

18

|

2

|

12,5

|

30

|

Ø 6

|

2

|

|

SLXP/032

|

Ø 32

|

20

|

2,5

|

13,5

|

40

|

Ø 7

|

3

|

|

SLXP/040

|

Ø 40

|

30

|

3

|

17,5

|

50

|

Ø 9

|

3,5

|

|

SLXP/050

|

Ø 50

|

28

|

3

|

20

|

60

|

Ø 9

|

3

|

|

SLXP/063

|

Ø 63

|

30

|

3

|

21

|

75

|

Ø 11

|

4,5

|

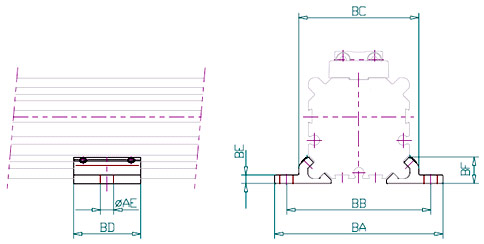

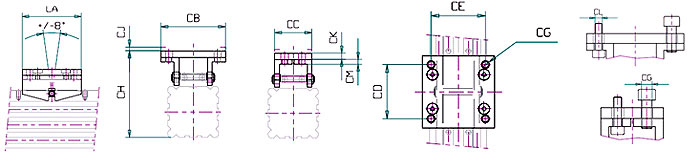

SLP Middle support

|

|

|

|

|

AE

|

AH

|

BA

|

BB

|

BC

|

BD

|

BE

|

BF

|

|

|

|

|

|

|

|

|

|

|

|

|

SLP/018

|

Ø 18

|

Ø 6

|

2

|

56

|

46

|

36,5

|

23

|

2,5

|

8,25

|

|

SLP/025

|

Ø 25

|

Ø 6

|

2

|

70

|

60

|

50

|

28

|

3,5

|

11

|

|

SLP/032

|

Ø 32

|

Ø 7

|

3

|

85

|

73

|

61,5

|

33

|

4

|

13,8

|

|

SLP/040

|

Ø 40

|

Ø 9

|

3

|

105

|

90

|

75

|

38

|

4,5

|

16

|

|

SLP/050

|

Ø 50

|

Ø 9

|

3

|

122

|

106

|

91

|

43

|

5

|

19

|

|

SLP/063

|

Ø 63

|

Ø 11

|

4,5

|

144

|

125

|

107

|

48

|

6

|

22

|

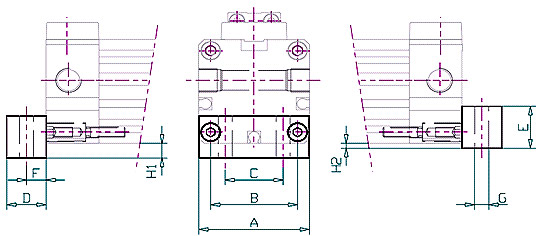

SLF Mounting block

|

|

|

|

|

A

|

B

|

C

|

D

|

E

|

F

|

G

|

H1

|

H2

|

Śruby

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SLF/018

|

Ø 18

|

30

|

23,5

|

14

|

10

|

14,5

|

5

|

Ø 4,5

|

6

|

2

|

M3 x 14

|

|

SLF/025

|

Ø 25

|

42

|

33

|

22

|

15

|

17

|

7,5

|

Ø 5,5

|

6

|

2

|

M4 x 20

|

|

SLF/032

|

Ø 32

|

52

|

41

|

23,5

|

15

|

20

|

7,5

|

Ø 7

|

6

|

3

|

M5 x 20

|

|

SLF/040

|

Ø 40

|

63

|

51

|

30

|

15

|

23

|

7,5

|

Ø 9

|

8

|

3

|

M6 x 20

|

|

SLF/050

|

Ø 50

|

78

|

63

|

39

|

16

|

26

|

8

|

Ø 9

|

8

|

3

|

M8 x 20

|

|

SLF/063

|

Ø 63

|

93

|

78

|

52

|

20

|

27,5

|

10

|

Ø 11

|

8

|

4,5

|

M8 x 20

|

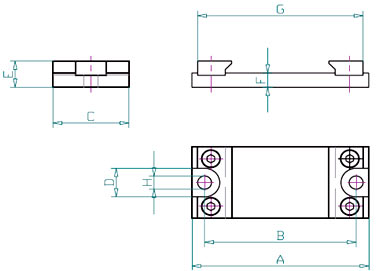

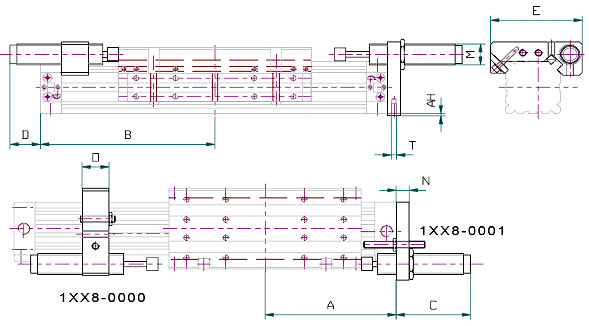

SLPP Middle support

|

|

|

|

|

A

|

B

|

C

|

D

|

E

|

F

|

G

|

H

|

|

|

|

|

|

|

|

|

|

|

|

|

SLPP/018

|

Ø 18

|

56

|

46

|

30

|

12

|

11

|

6

|

50,6

|

Ø 5,5

|

|

SLPP/025

|

Ø 25

|

70

|

60

|

30

|

12

|

13

|

6

|

65,5

|

Ø 5,5

|

|

SLPP/032

|

Ø 32

|

85

|

73

|

40

|

12,5

|

15

|

6

|

77,5

|

Ø 6,6

|

|

SLPP/040

|

Ø 40

|

105

|

90,5

|

40

|

16

|

18

|

8

|

90,5

|

Ø 9

|

|

SLPP/050

|

Ø 50

|

122

|

105

|

40

|

16

|

20,5

|

8

|

107,5

|

Ø 9

|

|

SLPP/063

|

Ø 63

|

144

|

125

|

50

|

19

|

21,5

|

8

|

122,5

|

Ø 11

|

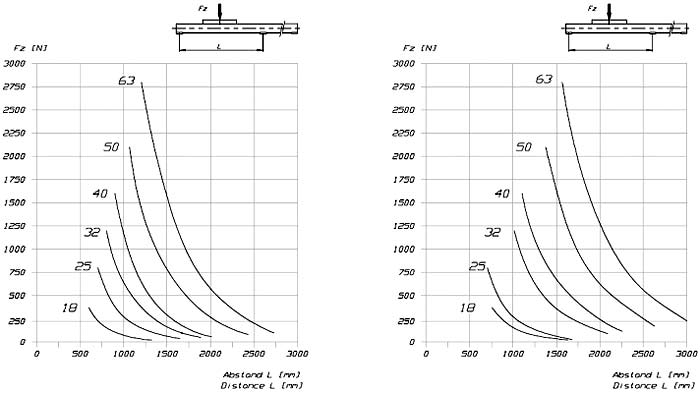

Deflection diagram

|

Fz

at deflection of 0,5 [mm]

|

Fz at

deflection of

1 [mm]

|

When using very long cylinders or

applying heavyloads, the tube deflection is to be taken into

consideration. One or more middle supports are to be used according to

the admissible deflection.

Example :

A cylinder ∅25 should deflect by a maximum of 0.5 mm when

applying a force FZ of 500N.

According to the diagram the cylinder can be 750 mm long.

Longer cylinders must have a middle support.

Other possibilities

In case very long cylinders are installed without supports, an

additional profile can be used as a support.

Examples: all versions with middle support and standard profiles.

|

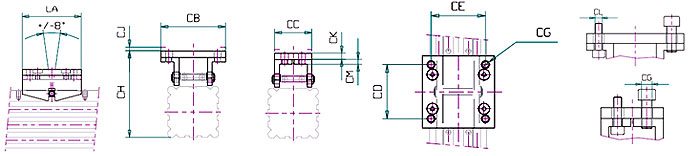

SLM Swinging bridge

The

swinging bridge will be used where additional guiding is mounted in

connection with a rodless cylinder.

The swinging bridge transfers the action power to the guiding element

without any restraint.

|

|

|

|

|

CA

|

CB

|

CD

|

CE

|

CG

|

CH

|

CJ

|

CK

|

CM

|

CL

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SLM/018

|

Ø 18

|

50

|

41,5

|

30

|

34

|

M5

|

54

|

2,5

|

4

|

4

|

M4

|

|

SLM/025

|

Ø 25

|

60

|

50

|

40

|

38

|

M5

|

70

|

3

|

4

|

4

|

M4

|

|

SLM/032

|

Ø 32

|

70

|

60

|

50

|

48

|

M6

|

86

|

3,5

|

6

|

6

|

M5

|

|

SLM/040

|

Ø 40

|

80

|

80

|

60

|

60

|

M8

|

107

|

4,5

|

8

|

8

|

M6

|

|

SLM/050

|

Ø 50

|

90

|

95

|

70

|

70

|

M8

|

123

|

4,5

|

8

|

8

|

M6

|

|

SLM/063

|

Ø 63

|

100

|

120

|

80

|

90

|

M10

|

145,5

|

5

|

8

|

8

|

M8

|

SLMK Swinging bridge

|

|

|

|

|

CA

|

CC

|

CD

|

CF

|

CG

|

CH

|

CJ

|

CK

|

CM

|

CL

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SLMK/018

|

Ø 18

|

50

|

25,5

|

30

|

9

|

M5

|

54

|

2,5

|

4

|

4

|

M4

|

|

SLMK/025

|

Ø 25

|

60

|

30

|

40

|

14

|

M5

|

70

|

3

|

4

|

4

|

M4

|

|

SLMK/032

|

Ø 32

|

70

|

37

|

50

|

16

|

M6

|

86

|

3,5

|

6

|

6

|

M5

|

|

SLMK/040

|

Ø 40

|

80

|

47

|

60

|

22

|

M8

|

107

|

4,5

|

8

|

8

|

M6

|

|

SLMK/050

|

Ø 50

|

90

|

56

|

70

|

30

|

M8

|

123

|

4,5

|

8

|

8

|

M6

|

|

SLMK/063

|

Ø 63

|

100

|

73

|

80

|

40

|

M10

|

145,5

|

5

|

8

|

8

|

M8

|

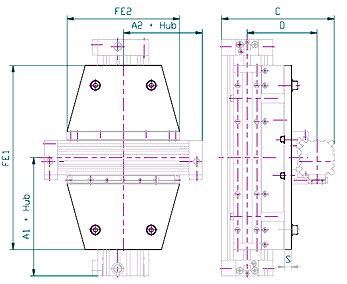

SLK cross support

The

cross support connects two guiding cylinders to a two-axis-system.

Guiding cylinders have to be ordered separately.

|

|

|

|

Kombinacja

siłowników

|

A1

|

A2

|

C

|

D

|

FE1

|

FE2

|

S

|

|

|

|

|

|

|

|

|

|

|

|

SLK/018-018

|

D18 –

D18

|

80

|

80

|

84

|

54

|

103

|

103

|

6

|

|

SLK/025-018

|

D25 –

D18

|

100

|

80

|

100

|

64

|

131

|

103

|

8

|

|

SLK/025-025

|

D25 –

D25

|

100

|

100

|

114

|

72

|

131

|

131

|

8

|

|

SLK/032-018

|

D32 –

D18

|

120

|

80

|

112

|

71

|

171

|

103

|

8

|

|

SLK/032-025

|

D32 –

D25

|

120

|

100

|

128

|

81

|

171

|

131

|

10

|

|

SLK/032-032

|

D32 –

D32

|

120

|

120

|

140

|

88

|

171

|

171

|

10

|

|

SLK/040-025

|

D40 –

D25

|

150

|

100

|

142

|

89,5

|

220

|

131

|

10

|

|

SLK/040-032

|

D40 –

D32

|

150

|

120

|

154

|

96,5

|

220

|

171

|

10

|

|

SLK/040-040

|

D40 –

D40

|

150

|

150

|

168

|

105

|

220

|

220

|

10

|

|

SLK/050-032

|

D50 –

D32

|

180

|

120

|

171

|

106

|

280

|

171

|

10

|

|

SLK/050-040

|

D50 –

D40

|

180

|

150

|

187

|

116,5

|

280

|

220

|

12

|

|

SLK/050-050

|

D50 –

D50

|

180

|

180

|

204

|

126

|

280

|

280

|

12

|

|

SLK/063-040

|

D63 –

D40

|

215

|

150

|

204,5

|

126,5

|

333

|

220

|

12

|

|

SLK/063-050

|

D63 –

D50

|

215

|

180

|

221,5

|

136

|

333

|

280

|

12

|

|

SLK/063-063

|

D63 –

D63

|

215

|

215

|

239

|

146

|

333

|

333

|

12

|

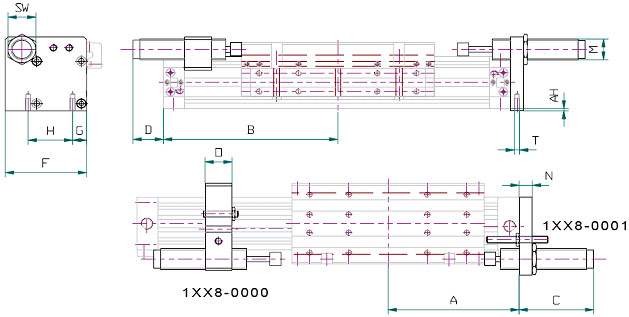

SLA Stop adjustment

|

|

|

|

|

Asl-g/Asl-gc

|

AH

|

Bsl-g/Bsl-gc

|

C

|

D

|

E

|

M

|

N

|

O

|

T

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SLA/018

|

Ø 18

|

80/57,5

|

2

|

113/90,5

|

32

|

max. 25

|

57

|

M10x1

|

8

|

15

|

M3 x 10

|

|

SLA/025

|

Ø 25

|

100/67,5

|

2

|

117,5/85

|

37

|

max.40

|

72

|

M14x1,5

|

10

|

20

|

M4 x 10

|

|

SLA/032

|

Ø 32

|

120/77,5

|

3

|

135,5/90

|

70

|

max. 30

|

84

|

M14x1,5

|

12

|

20

|

M5 x 12

|

|

SLA/040

|

Ø 40

|

150/95

|

3

|

165/110

|

65

|

max. 50

|

105

|

M25x1,5

|

15

|

30

|

M6 x 15

|

|

SLA/050

|

Ø 50

|

180/105

|

3

|

195/140

|

80

|

max. 65

|

126

|

M25x1,5

|

15

|

30

|

M8 x 20

|

|

SLA/063

|

Ø 63

|

215/125

|

4,5

|

250/160

|

80

|

max. 65

|

140

|

M25x1,5

|

15

|

40

|

M8 x 20

|

SLAE Stop adjustment

|

|

|

|

|

|

Asl-g/Asl-gc

|

AH

|

Bsl-g/Bsl-gc

|

C

|

D

|

F

|

G

|

H

|

M

|

N

|

O

|

SW

|

T

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SLAE/018

|

Ø 18

|

80/57,5

|

2

|

113/90,5

|

32

|

max. 25

|

43,5

|

8

|

23,5

|

M10x1

|

8

|

15

|

13

|

M3 x 10

|

|

SLAE/025

|

Ø 25

|

100/67,5

|

2

|

117,5/85

|

37

|

max.40

|

57

|

12,5

|

33

|

M14x1,5

|

10

|

20

|

17

|

M4 x 10

|

|

SLAE/032

|

Ø 32

|

120/77,5

|

3

|

135,5/90

|

70

|

max. 30

|

70

|

14,5

|

41

|

M14x1,5

|

12

|

20

|

17

|

M5 x 12

|

|

SLAE/040

|

Ø 40

|

150/95

|

3

|

165/110

|

65

|

max. 50

|

93

|

16

|

51

|

M25x1,5

|

15

|

30

|

32

|

M6 x 15

|

|

SLAE/050

|

Ø 50

|

180/105

|

3

|

195/140

|

80

|

max. 65

|

102

|

22,5

|

63

|

M25x1,5

|

15

|

30

|

32

|

M8 x 20

|

|

SLAE/063

|

Ø 63

|

215/125

|

4,5

|

250/160

|

80

|

max. 65

|

118,5

|

20

|

78

|

M25x1,5

|

15

|

40

|

32

|

M8 x 20

|

SLV Reed switch

|